Company Introduction

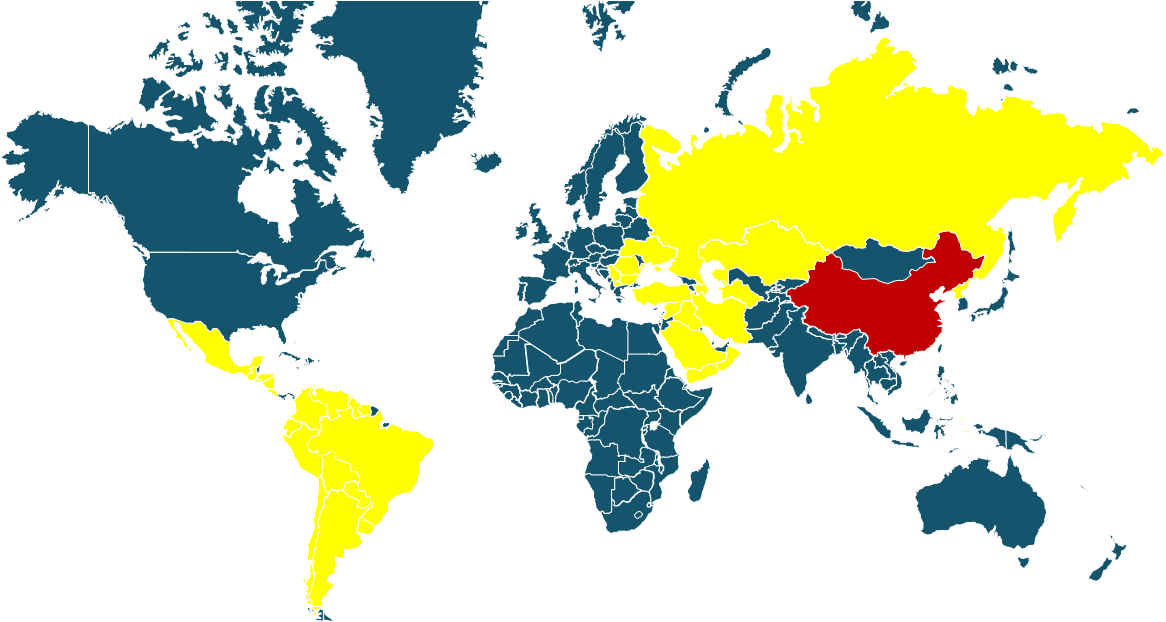

Our location

St-Mill Company (unified social credit Identifier 91370212MA94QYEM08) is located in the beautiful coastal city of Qingdao, Shandong Province. Qingdao Port is the largest import and export port in northern China, trading with over 450 ports in 130 countries and regions around the world. It is an important international trade port and maritime transportation hub on the west coast of the Pacific Ocean.